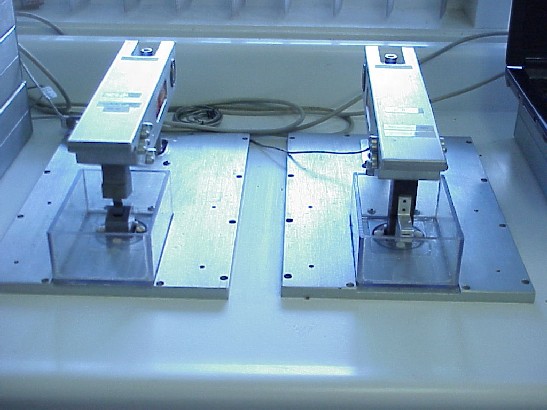

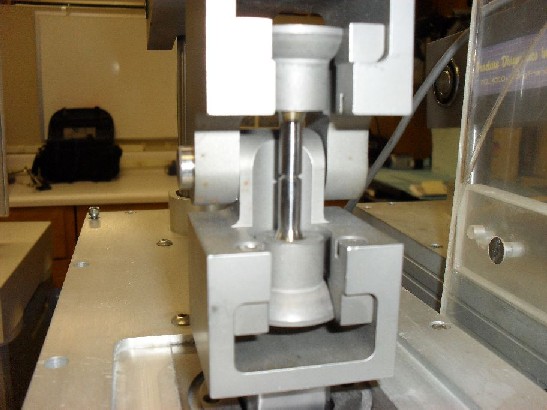

4-Point Bending Frame

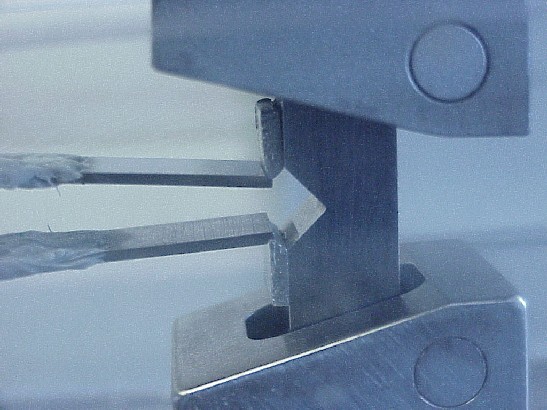

Model FDI 1200-B Rising Step LoadTM Bend Test System This unit utilizes a constant displacement bending arm precisely controlled through software developed especially for this equipment. Although designed for ASTM F519 testing, by combining its use of 4-Point Bending and various fixtures, the versatile FDI 1200-B test system can perform a broad variety of tests, including quality control tests for plating in bending on single edged notched square bars, and with the right fixtures, the same bend frame can test actual parts such as Fasteners, even C-Rings in compression and Tensile Coupons in tension! With the use of Certified Test Specimen, in 24 HOURS, you can QUANTITATIVLY measure the hydrogen generated by any specific plating process QUICKLY giving you useful information to help you improve the quality of your parts or plating baths. |

|

The software uses a graphical interface combining a unique control of all testing parameters and simplicity of operation. Data generated can be filed into and analyzed by many standard data base programs. |

|

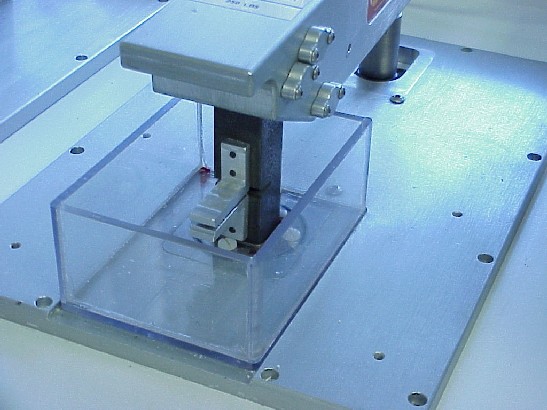

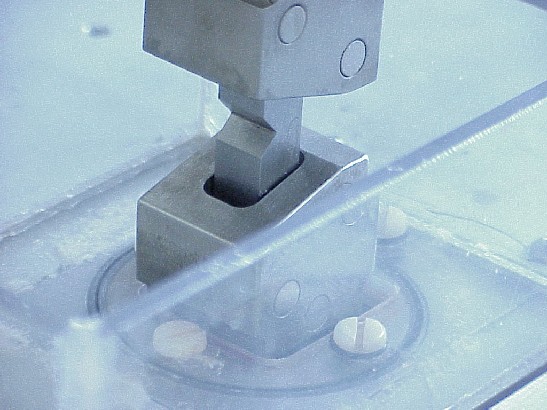

Bend Frame Environmental Testing Upgrades These upgrades take the Model FDI 1200-B but includes additional Scientific Software, a Scientific Controller, an Environmental reservoir, a Platinum Electrode , and a Ag/AgCl Reference Electrode. This allows the Bending Frame to become a powerful research and investigative tool able to emulate field conditions and measure the response of materials, Parts or substrates. With this capability, it is possible to determine if a material, part or substrate is already embrittled by hydrogen; if it would be susceptible to embrittlement when used in real world applications; as well as its behavior in a worst case scenario all at a rate capable of over 1000 tests a year. This unit comes with a Motor Controller, calibrated load cell, Scientific Controller, Environmental reservoir, Platinum Auxiliary Electrode , and a Ag/AgCl Reference Electrode, upgraded Scientific operating software, a computer able to run multiple FDI Testing Systems at once, and a 2-day installation and demonstration. An optional operating instruction course is also available. |

|

Test Capability: |

Construction: Stainless Steel and Aluminum Height: 12" Width: 9.5" Weight: 75 pounds Power: 110/125 Volt AC 50/60 Hz Single Phase |